How Are Bio Ethanol Burners Manufactured?

Discover the fascinating process behind the manufacturing of bio ethanol burners, a sustainable and environmentally-friendly alternative to traditional fuel sources. Dive into the intricate steps and innovative techniques used to create these efficient and stylish heating solutions. Join us as we explore the inner workings of bio ethanol burner production and uncover the benefits of incorporating them into your home or business.

- Introduction to Bio Ethanol Burners

to Bio Ethanol Burners

Bio ethanol burners have gained popularity in recent years as a sustainable and eco-friendly alternative to traditional fuel sources. These burners offer a clean and efficient way to heat and light homes, without the harmful emissions associated with fossil fuels. In this article, we will explore how bio ethanol burners are manufactured, and the materials and processes involved in their production.

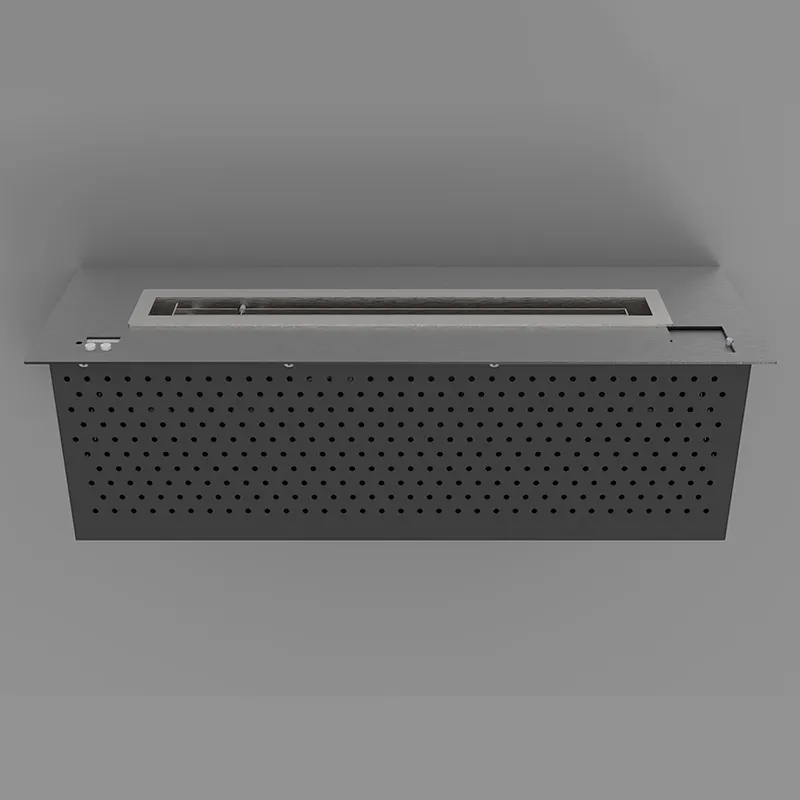

The first step in manufacturing a bio ethanol burner is selecting the materials for the burner itself. These burners are typically made from high-quality stainless steel or other heat-resistant materials to ensure durability and safety. Stainless steel is a popular choice for its strength and resistance to corrosion, making it a reliable option for use in bio ethanol burners.

Once the materials are selected, the manufacturing process begins. The burner body is typically constructed using a combination of welding and metal fabrication techniques. This involves shaping and forming the metal to create the burner's design, which can range from simple and sleek to more intricate and decorative styles.

The burner is then fitted with a mechanism for controlling the flow of bio ethanol fuel. This can be a simple manual switch or a more advanced electronic system, depending on the model of the burner. The fuel is added to the burner's reservoir, where it is ignited to produce a clean and efficient flame.

In addition to the burner body and fuel mechanism, bio ethanol burners may also include safety features such as automatic shut-off valves and temperature sensors. These features help to ensure that the burner operates safely and effectively, reducing the risk of accidents or malfunctions.

Once the burner is assembled, it undergoes testing to ensure that it meets safety and quality standards. This typically involves testing the burner's performance under various conditions, such as different fuel levels and burn times. Any issues or defects are addressed and corrected before the burner is ready for sale to customers.

Overall, the manufacturing process of bio ethanol burners involves careful attention to detail and quality control to ensure that each burner meets the highest standards of safety and efficiency. By using sustainable materials and eco-friendly fuels, bio ethanol burners offer a cleaner and more sustainable alternative to traditional heating and lighting sources.

- Materials and Components Used in Manufacturing

Bio ethanol burners have gained popularity in recent years as a sustainable and eco-friendly alternative to traditional wood-burning and gas-powered fireplaces. These burners are not only stylish and versatile but also efficient and clean-burning, making them a popular choice for environmentally conscious consumers. In this article, we will delve into the manufacturing process of bio ethanol burners, focusing on the materials and components used in their production.

One of the key materials used in the manufacturing of bio ethanol burners is stainless steel. This high-quality material is chosen for its durability, heat resistance, and sleek aesthetic appeal. Stainless steel is also a corrosion-resistant material, ensuring that the bio ethanol burners will maintain their appearance and functionality over time. The use of stainless steel in the manufacturing process also adds a touch of sophistication and modernity to the burners, making them a stylish addition to any home or commercial space.

Another important component used in the production of bio ethanol burners is tempered glass. This transparent and heat-resistant material is often used for the casing or housing of the burners, allowing users to enjoy the mesmerizing flames while ensuring safety and durability. Tempered glass is specifically designed to withstand high temperatures without shattering or cracking, making it a reliable choice for bio ethanol burners. The use of tempered glass in the manufacturing process also adds a contemporary and elegant touch to the burners, enhancing their visual appeal.

In addition to stainless steel and tempered glass, bio ethanol burners also utilize other components such as burner inserts, fuel tanks, and flame regulators. These components are carefully selected and designed to work together seamlessly, ensuring the optimal performance and safety of the burners. The burner inserts, for example, are made from high-quality materials such as ceramic or metal to ensure efficient combustion of the bio ethanol fuel. The fuel tanks are typically made from durable materials such as stainless steel or aluminum, and are designed to securely hold and dispense the bio ethanol fuel. The flame regulators, on the other hand, are responsible for controlling the size and intensity of the flames, allowing users to adjust the heat output according to their preferences.

Overall, the manufacturing process of bio ethanol burners involves the careful selection and integration of high-quality materials and components, resulting in a product that is not only stylish and versatile but also efficient and environmentally friendly. With their sleek design, clean-burning flames, and sustainable fuel source, bio ethanol burners are a popular choice for those looking to add warmth and ambiance to their living spaces while minimizing their carbon footprint. Whether used in residential homes, commercial settings, or outdoor spaces, bio ethanol burners offer a sophisticated and eco-friendly heating solution that is both functional and aesthetically pleasing.

- Manufacturing Process of Bio Ethanol Burners

Bio Ethanol Burners have become increasingly popular in recent years as a sustainable and eco-friendly alternative to traditional gas or electric burners. These burners are designed to be fueled by bio ethanol, a renewable energy source derived from plants such as corn, sugarcane, and switchgrass. In this article, we will explore the manufacturing process of bio ethanol burners, from the raw materials used to the final product.

The first step in manufacturing bio ethanol burners is sourcing the raw materials. The main component of these burners is stainless steel, a durable and heat-resistant material that is ideal for withstanding the high temperatures generated by the burner. In addition to stainless steel, other materials such as tempered glass, ceramic fibers, and aluminum are also used in the construction of bio ethanol burners.

Once the raw materials are sourced, the manufacturing process begins. The first step is to cut and shape the stainless steel sheets into the desired components of the burner, such as the base, the burner insert, and the outer casing. These components are then welded together to form the structure of the burner. Special attention is given to the joints and seams to ensure that they are airtight and leak-proof.

Next, the burner is fitted with the necessary components, such as the fuel reservoir, the burner insert, and the flame guard. The fuel reservoir is where the bio ethanol is stored, while the burner insert is where the fuel is ignited to produce a flame. The flame guard is a safety feature that prevents accidental contact with the flame and helps to distribute heat evenly.

Once all the components are assembled, the burner is subjected to a series of quality control tests to ensure that it meets the manufacturer's standards. These tests include checks for leaks, proper ignition, heat output, and overall functionality. Any defects or issues are addressed and corrected before the burner is deemed ready for sale.

After passing the quality control tests, the burner is given a final finish, which may include polishing, painting, or coating to enhance its aesthetic appeal. The finished product is then packaged and shipped to retailers or distributors, where it will be made available to consumers.

In conclusion, the manufacturing process of bio ethanol burners involves sourcing high-quality materials, cutting and shaping components, welding and assembling the burner, conducting quality control tests, and adding a final finish. The end result is a stylish and efficient burner that is not only environmentally friendly but also a chic addition to any home or commercial space. Bio ethanol burners are a testament to the growing trend towards sustainable and eco-conscious living, providing consumers with a clean energy option for heating and ambiance.

- Quality Control in Bio Ethanol Burner Production

Bio ethanol burners are a popular alternative to traditional wood or gas fireplaces, offering a clean and eco-friendly way to enjoy the warmth and ambiance of a real flame. But have you ever wondered how these bio ethanol burners are actually manufactured? In this article, we will take a detailed look at the production process, with a specific focus on quality control.

The production of bio ethanol burners starts with the selection of high-quality materials. Stainless steel is often used for the body of the burner, as it is durable and resistant to corrosion. The burner may also include components such as a flame screen, fuel tray, and ignition system. These parts are carefully designed and fabricated to ensure optimal performance and safety.

Once the materials are sourced, the manufacturing process begins. The first step is cutting the stainless steel sheets into the desired shapes and sizes. Precision is crucial in this step to ensure that all components fit together seamlessly. The pieces are then welded together by skilled craftsmen to form the body of the burner.

Quality control is integrated at every stage of the manufacturing process to maintain high standards. Inspections are conducted to check for any defects or imperfections in the materials or workmanship. Measurements are taken to ensure that each component meets the specified dimensions. Any deviations from the standard are corrected immediately to prevent issues down the line.

After the body of the burner is assembled, it undergoes a series of tests to ensure functionality and safety. The flame screen is inspected to verify that it will effectively diffuse the flame and prevent any flare-ups. The fuel tray is checked to ensure proper ventilation and optimal fuel flow. The ignition system is tested to guarantee reliable and consistent ignition of the bio ethanol fuel.

Once the burner passes all quality control checks, it is then polished and finished to give it a sleek and attractive appearance. The final product is carefully packaged and prepared for shipping to retailers and customers around the world. Each bio ethanol burner is accompanied by detailed instructions for installation and use to ensure a hassle-free experience for the end-user.

In conclusion, the manufacturing of bio ethanol burners involves a combination of skilled craftsmanship, rigorous quality control, and attention to detail. From the selection of materials to the final inspection, every step is carefully orchestrated to create a product that is not only functional and safe but also aesthetically pleasing. Next time you gather around a bio ethanol burner, take a moment to appreciate the craftsmanship and care that went into producing it.

- Environmental Benefits of Bio Ethanol Burners

Bio Ethanol Burners have become increasingly popular in recent years as a clean and sustainable alternative to traditional wood-burning fireplaces. In this article we will explore the environmental benefits of bio ethanol burners and delve into how they are manufactured.

One of the key advantages of bio ethanol burners is their eco-friendly nature. Bio ethanol is a renewable energy source that is derived from plants such as corn, sugarcane, and wheat. Unlike fossil fuels, bio ethanol is carbon-neutral, meaning it does not release any harmful emissions when burned. This makes bio ethanol burners a much cleaner option for heating and lighting compared to traditional wood-burning fireplaces or gas-powered heaters.

In addition to being environmentally friendly, bio ethanol burners also offer numerous other benefits. They are easy to use, requiring no chimney or ventilation system, and can be placed virtually anywhere in a room. Bio ethanol burners also produce a clean and odorless flame, eliminating the need for cleaning up ash or soot after each use.

The manufacturing process of bio ethanol burners is relatively straightforward. The main components of a bio ethanol burner include a reservoir for holding the bio ethanol fuel, a burner unit, and a mechanism for adjusting the size of the flame. The burner unit is usually made of stainless steel or another heat-resistant material to ensure durability and safety.

To manufacture a bio ethanol burner, the first step is to design and fabricate the burner unit. This involves cutting and shaping the metal components to the desired specifications. The reservoir is then attached to the burner unit, along with any additional features such as a safety shut-off valve or a decorative surround.

Once the burner unit is complete, it is tested to ensure it is functioning correctly and safely. The burner is then filled with bio ethanol fuel and ignited to test the flame. Any adjustments that need to be made are done at this stage to ensure optimal performance.

Overall, bio ethanol burners offer numerous environmental benefits compared to traditional heating methods. By using renewable bio ethanol fuel, they help reduce greenhouse gas emissions and promote a more sustainable way of heating and lighting homes. Additionally, their easy installation and clean burning flame make them a practical and stylish choice for modern living spaces.

Conclusion

In conclusion, the manufacturing process of bio ethanol burners involves a series of intricate steps that require precision and expertise. From sourcing high-quality materials to assembling the components and testing for safety and functionality, manufacturers must adhere to strict standards to ensure the production of efficient and reliable burners. By understanding the intricacies of how bio ethanol burners are manufactured, consumers can gain a deeper appreciation for the craftsmanship and innovation that goes into creating these environmentally-friendly heating solutions. As the demand for sustainable and energy-efficient products continues to rise, it is clear that bio ethanol burners will play a crucial role in shaping the future of eco-friendly heating technologies.