How To Ensure Quality In Bio Ethanol Burner Manufacturing?

Are you in the market for a bio ethanol burner but unsure about how to ensure quality in the manufacturing process? Look no further! In this article, we will delve into the key steps and considerations necessary to guarantee top-notch quality in bio ethanol burner manufacturing. Whether you're a consumer or a manufacturer, understanding these essential factors is crucial for making informed decisions and achieving the best results. Let's explore how you can ensure quality in the production of bio ethanol burners.

- Understanding the importance of quality standards in bio ethanol burner manufacturing

In the world of sustainable energy solutions, bio ethanol burners have emerged as a popular choice for environmentally conscious consumers. These innovative devices offer a clean-burning alternative to traditional fossil fuel-based burners, making them a valuable addition to any eco-friendly home or business. However, in order to ensure that bio ethanol burners are truly effective and safe to use, it is essential to prioritize quality standards in their manufacturing process.

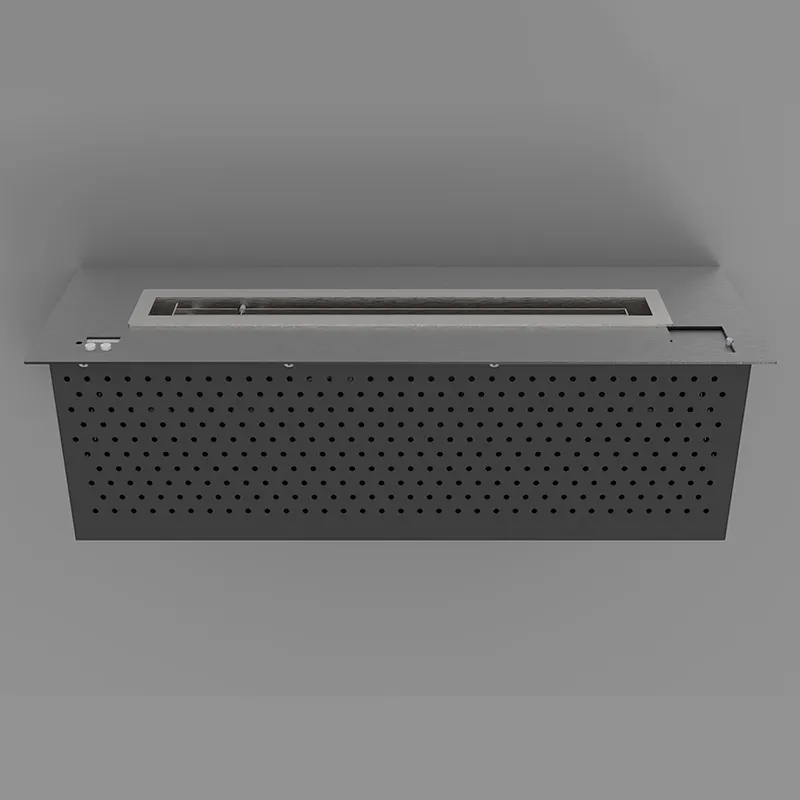

One of the key factors to consider when manufacturing bio ethanol burners is the quality of the materials used. High-quality materials, such as stainless steel and tempered glass, not only enhance the aesthetic appeal of the burner but also ensure its durability and longevity. By investing in superior materials, manufacturers can guarantee that their products will withstand the rigors of regular use and provide reliable performance for years to come.

Another important element of quality assurance in bio ethanol burner manufacturing is adherence to strict safety standards. Bio ethanol is a highly flammable substance, and if not handled properly, it can pose a serious fire hazard. In order to mitigate this risk, manufacturers must implement rigorous safety protocols throughout the production process, from the design phase to the final product testing. By prioritizing safety, manufacturers can instill confidence in consumers and establish themselves as reputable providers of bio ethanol burners.

In addition to materials and safety standards, manufacturers must also consider the overall design and functionality of bio ethanol burners. A well-designed burner not only enhances the visual appeal of a space but also ensures optimal combustion efficiency and heat output. By incorporating features such as adjustable flame controls and automatic shut-off mechanisms, manufacturers can create a product that is both user-friendly and performance-driven.

Furthermore, it is essential for manufacturers to prioritize sustainability in the production of bio ethanol burners. As a renewable energy source, bio ethanol offers an environmentally friendly alternative to traditional fuels. By utilizing sustainable manufacturing practices, such as recycling materials and minimizing waste, manufacturers can further reduce their carbon footprint and support the transition to a more sustainable energy future.

Overall, the importance of quality standards in bio ethanol burner manufacturing cannot be overstated. By prioritizing high-quality materials, safety protocols, design considerations, and sustainability practices, manufacturers can ensure that their products meet the highest standards of performance, safety, and environmental responsibility. As consumers increasingly prioritize eco-friendly solutions, manufacturers who embrace these standards will be well positioned to succeed in the competitive market for bio ethanol burners.

- Implementing strict quality control measures in production processes

Bio Ethanol Burners have become increasingly popular in recent years as a sustainable and environmentally-friendly alternative to traditional gas and wood-burning fireplaces. These burners are designed to burn clean bio ethanol fuel, which is made from renewable sources such as corn, sugarcane, and other plant materials. However, in order to ensure the quality of these burners, it is crucial to implement strict quality control measures in the production processes.

One of the key aspects of ensuring quality in Bio Ethanol Burner manufacturing is the use of high-quality materials. These burners are exposed to high temperatures and flames, so it is important that they are made from materials that can withstand these conditions. Stainless steel, tempered glass, and ceramic are commonly used materials in Bio Ethanol Burner manufacturing due to their durability and heat resistance.

In addition to using the right materials, manufacturers must also pay close attention to the design and construction of the burners. A well-designed burner will not only look aesthetically pleasing but will also function efficiently and safely. It is important to consider factors such as airflow, fuel distribution, and flame control when designing a Bio Ethanol Burner to ensure optimal performance.

Quality control measures should be implemented at every stage of the manufacturing process, from sourcing materials to final assembly. This includes conducting thorough inspections of incoming materials to ensure they meet quality standards, as well as regular testing and inspections throughout the production process. Any defects or issues should be identified and addressed immediately to prevent them from affecting the quality of the final product.

Another important aspect of quality control in Bio Ethanol Burner manufacturing is ensuring that the burners meet safety standards and regulations. This includes testing the burners for leaks, ensuring proper ventilation and airflow, and providing clear instructions for use and maintenance. Compliance with safety standards is not only important for ensuring the safety of consumers but also for protecting the reputation of the manufacturer.

In conclusion, implementing strict quality control measures in the production processes of Bio Ethanol Burners is essential for ensuring the quality, safety, and performance of these environmentally-friendly fireplaces. By using high-quality materials, paying attention to design and construction, and adhering to safety standards, manufacturers can produce Bio Ethanol Burners that meet the highest quality standards and provide consumers with a reliable and sustainable heating option.

- Selecting high-quality materials for bio ethanol burner construction

When it comes to manufacturing bio ethanol burners, ensuring quality is of utmost importance. One key aspect of this process is selecting high-quality materials for construction. By using top-grade materials, manufacturers can guarantee that their bio ethanol burners are both durable and efficient in providing heat without compromising safety.

The first step in selecting materials for bio ethanol burner construction is to consider the burner's design and functionality. Different types of bio ethanol burners require specific materials to ensure optimal performance. For example, wall-mounted burners may require heat-resistant materials that can withstand high temperatures, while table-top burners may benefit from lightweight yet sturdy materials for portability.

One of the most important materials to consider for bio ethanol burner construction is the burner itself. The burner must be able to withstand high temperatures generated by the ethereal flame without warping or deteriorating over time. Materials such as stainless steel or ceramic are commonly used due to their heat-resistant properties. Stainless steel is known for its durability and resistance to corrosion, making it an ideal choice for bio ethanol burner construction.

In addition to the burner, the fuel container is also a crucial component of bio ethanol burners. The fuel container must be made of a material that is compatible with ethanol fuel and can safely contain the liquid without leaking. Glass and stainless steel are popular choices for fuel containers, as they are both non-reactive to ethanol and have excellent heat-resistant properties.

Furthermore, the burner's casing and casing must also be carefully selected to ensure quality and longevity. The casing should be made of a material that can withstand high temperatures and protect the burner's components from damage. Aluminum and powder-coated steel are common choices for casing materials, as they are lightweight, durable, and resistant to rust.

Overall, selecting high-quality materials for bio ethanol burner construction is essential to ensuring the burner's performance and safety. By choosing materials that are heat-resistant, durable, and compatible with ethanol fuel, manufacturers can create bio ethanol burners that are not only efficient but also long-lasting. Investing in quality materials for construction will ultimately result in a superior product that exceeds customer expectations and provides reliable heat for years to come.

- Testing and monitoring burner performance to ensure quality

Bio ethanol burners have become increasingly popular in recent years as a sustainable and eco-friendly alternative to traditional fossil fuel burners. These burners are commonly used in fireplaces, stoves, and outdoor heaters, providing a clean and efficient way to heat and cook. However, ensuring the quality of bio ethanol burners is crucial to their performance and safety. In this article, we will discuss the importance of testing and monitoring burner performance to maintain high standards in bio ethanol burner manufacturing.

When it comes to bio ethanol burners, safety is paramount. Poorly manufactured burners can pose a risk of leaking fuel or malfunctioning, leading to potential fires or explosions. To prevent such hazards, manufacturers must adhere to strict quality control measures throughout the production process. This includes thorough testing of burner components and monitoring burner performance to detect any defects or inefficiencies.

One of the key aspects of ensuring quality in bio ethanol burner manufacturing is testing the burner's performance under various conditions. This involves conducting tests to evaluate the burner's efficiency, heat output, and emissions. By measuring these factors, manufacturers can ensure that the burner meets industry standards and operates safely and effectively.

Another important aspect of quality assurance in bio ethanol burner manufacturing is monitoring burner performance over time. This can be done through regular maintenance and inspections to detect any signs of wear or damage. By identifying and addressing issues early on, manufacturers can prevent potential safety hazards and ensure the longevity of the burner.

In addition to testing and monitoring burner performance, manufacturers must also pay attention to the quality of materials used in the production of bio ethanol burners. High-quality materials are essential for the durability and efficiency of the burner. By using premium materials, manufacturers can reduce the risk of corrosion, leaks, and other issues that could compromise the burner's performance.

Furthermore, proper assembly and installation of bio ethanol burners are crucial for ensuring quality. Manufacturers should provide clear instructions and guidelines for assembling and installing the burner to prevent improper setup and potential malfunctions. Additionally, manufacturers should offer training and support to users to ensure they understand how to properly operate and maintain the burner.

Overall, testing and monitoring burner performance are essential steps in ensuring the quality of bio ethanol burners. By following strict quality control measures, manufacturers can produce safe and reliable burners that meet industry standards and provide efficient heating solutions. By investing in quality assurance processes, manufacturers can build trust with consumers and uphold the reputation of their brand in the market.

- Ensuring customer satisfaction through reliable and durable bio ethanol burners

Bio Ethanol burners have become a popular choice for homeowners looking to add a touch of elegance and ambiance to their living spaces. The clean-burning fuel, derived from renewable resources such as corn, sugarcane, and other plant-based materials, offers a sustainable and eco-friendly alternative to traditional wood-burning fireplaces.

When it comes to manufacturing bio ethanol burners, ensuring quality is essential to guarantee customer satisfaction. Customers rely on these burners to provide them with reliable and durable performance, as well as safety and convenience. In this article, we will explore how manufacturers can ensure quality in bio ethanol burner manufacturing to meet the needs and expectations of their customers.

One of the key factors in ensuring quality in bio ethanol burner manufacturing is selecting the right materials. High-quality materials, such as stainless steel, ensure durability and longevity, providing customers with a product that will last for years to come. Manufacturers must carefully source materials from reputable suppliers to guarantee the integrity of the burner.

In addition to materials, the design of the burner plays a crucial role in its quality. A well-designed burner will not only be aesthetically pleasing but will also function efficiently and safely. Manufacturers must invest time and resources into research and development to create innovative designs that meet the needs of customers while adhering to safety standards.

Testing and quality control are also essential steps in the manufacturing process. Manufacturers should conduct rigorous testing on each burner to ensure that it meets safety and performance requirements. Quality control measures should be implemented throughout the manufacturing process to identify any potential issues and address them before the product reaches the customer.

Customer feedback is another valuable tool for ensuring quality in bio ethanol burner manufacturing. By soliciting feedback from customers, manufacturers can gain insights into their satisfaction levels and areas for improvement. This feedback can be used to make necessary adjustments to the manufacturing process and product design to better meet the needs of customers.

Ultimately, ensuring quality in bio ethanol burner manufacturing is vital for customer satisfaction. By selecting high-quality materials, designing innovative products, implementing rigorous testing and quality control measures, and soliciting customer feedback, manufacturers can create reliable and durable burners that exceed customer expectations. By prioritizing quality, manufacturers can build a reputation for excellence and establish long-lasting relationships with their customers.

Conclusion

In conclusion, ensuring quality in bio ethanol burner manufacturing is crucial for the safety and satisfaction of consumers. By implementing strict quality control measures at every stage of production, manufacturers can guarantee that their products meet high standards of durability, efficiency, and sustainability. Additionally, ongoing research and innovation in materials and technology will continue to drive advancements in bio ethanol burner manufacturing, leading to more environmentally friendly and economically viable solutions for heating and energy needs. By prioritizing quality and continuous improvement, manufacturers can meet the growing demand for sustainable energy solutions and contribute to a cleaner, more sustainable future for all.