What Materials Are Used In Bio Ethanol Burner Production?

Are you curious about the materials that go into creating bio ethanol burners? Look no further! In this article, we will delve into the various components used in the production of these eco-friendly and efficient devices. From the fuel itself to the construction of the burner, discover the sustainable materials that make bio ethanol burners an ideal choice for heating and ambiance. Let's uncover the science behind these innovative products and explore the environmental benefits they offer.

Introduction to Bio Ethanol Burners

In the world of sustainable heating and design, bio ethanol burners are becoming increasingly popular as an eco-friendly alternative to traditional fireplace options. These stylish and innovative heating solutions offer a clean-burning and efficient way to heat a space without the need for a chimney or gas line. In this article, we will delve into the world of bio ethanol burners and explore the materials used in their production.

Bio ethanol burners are a type of fireplace that utilize bio ethanol fuel, a renewable energy source produced from plants such as sugarcane, corn, and switchgrass. This clean-burning fuel is derived from the fermentation of these plants, making it an environmentally friendly option for heating your home.

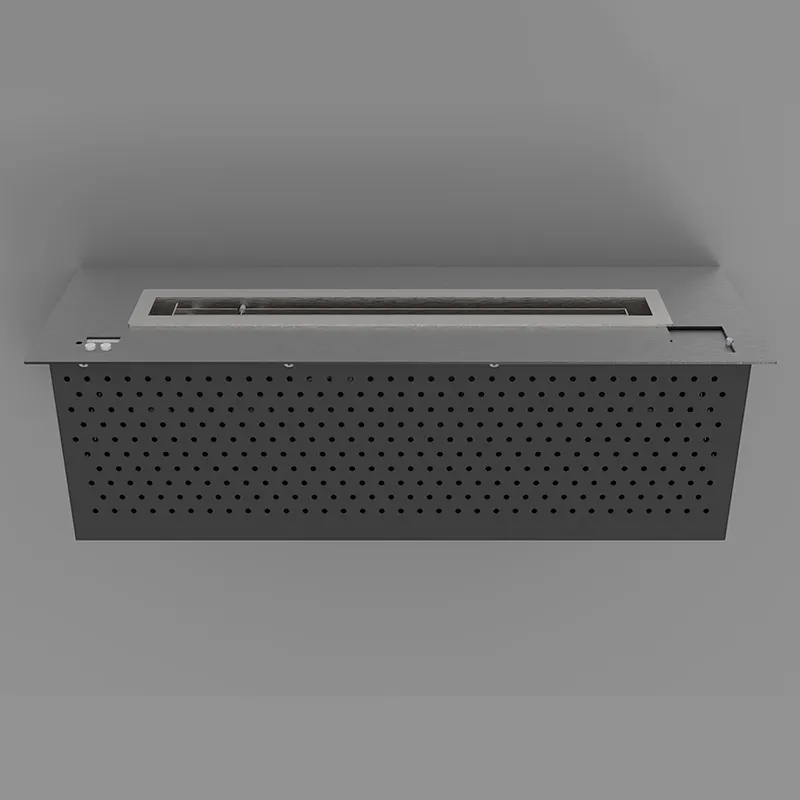

When it comes to the materials used in the production of bio ethanol burners, there are a few key components that make up these stylish and functional heating solutions. The first material to consider is stainless steel, which is often used in the construction of the burner itself. Stainless steel is a durable and corrosion-resistant material that is well-suited for high-temperature applications, making it an ideal choice for bio ethanol burners.

Another important material used in the production of bio ethanol burners is tempered glass. Tempered glass is a type of safety glass that is highly resistant to heat and impact, making it a safe and stylish choice for the viewing panels of bio ethanol burners. This transparent material allows you to enjoy the mesmerizing flame of the bio ethanol burner while providing an added layer of protection.

In addition to stainless steel and tempered glass, bio ethanol burners may also incorporate other materials such as ceramic and porcelain. These materials are often used in the burner inserts or decorative elements of the burner, adding a touch of elegance and sophistication to the overall design.

One of the key benefits of bio ethanol burners is their versatility in terms of design. These innovative heating solutions come in a variety of shapes, sizes, and styles, making them a versatile option for any space. Whether you prefer a sleek and modern design or a more traditional and rustic look, there is a bio ethanol burner to suit your aesthetic preferences.

In conclusion, bio ethanol burners are a sustainable and stylish heating option that offer a clean-burning alternative to traditional fireplaces. The materials used in the production of these innovative heating solutions, such as stainless steel, tempered glass, ceramic, and porcelain, contribute to their durability, safety, and aesthetic appeal. If you are looking for a eco-friendly and efficient way to heat your home, consider investing in a bio ethanol burner for both warmth and style.

Commonly Used Materials in Bio Ethanol Burner Production

Bio Ethanol Burners have become increasingly popular in recent years as more people are looking for eco-friendly and sustainable heating solutions. These burners are used for heating purposes in homes, offices, restaurants, and outdoor spaces. In the production of bio ethanol burners, manufacturers utilize a variety of materials to ensure safety, efficiency, and longevity.

One of the most commonly used materials in bio ethanol burner production is stainless steel. This durable and corrosion-resistant material is ideal for constructing the burner body, burner plate, and fuel container. Stainless steel is known for its high melting point and ability to withstand high temperatures, making it a reliable choice for bio ethanol burners. Additionally, stainless steel is easy to clean and maintain, making it a practical material for use in residential and commercial settings.

Another important material used in bio ethanol burner production is tempered glass. Tempered glass is often used to create a protective barrier around the flame, preventing accidents and enhancing the overall safety of the burner. Tempered glass is heat-resistant and can withstand extreme temperatures without shattering, making it an essential component of bio ethanol burners. In addition, the transparency of tempered glass allows users to enjoy the beauty of the flame while ensuring that it is safely contained.

Ceramic fiber is another material commonly used in bio ethanol burner production. This lightweight and heat-resistant material is often used as insulation inside the burner to protect surrounding surfaces from heat damage. Ceramic fiber helps to improve the efficiency of the burner by retaining heat and ensuring that it is evenly distributed. Additionally, ceramic fiber helps to reduce the risk of accidental burns or fire hazards by containing the heat within the burner.

In addition to stainless steel, tempered glass, and ceramic fiber, manufacturers may also use other materials such as aluminum, brass, or copper in bio ethanol burner production. These materials are chosen for their specific properties, including conductivity, durability, and aesthetics. Ultimately, the combination of different materials in bio ethanol burner production helps to create a versatile and reliable heating solution for a wide range of applications.

Overall, the materials used in bio ethanol burner production play a crucial role in the safety, efficiency, and performance of these heating devices. By choosing high-quality materials such as stainless steel, tempered glass, and ceramic fiber, manufacturers can ensure that bio ethanol burners meet the highest standards of quality and reliability. As demand for eco-friendly heating solutions continues to grow, the use of sustainable materials in bio ethanol burner production will be essential in meeting the needs of consumers and protecting the environment.

Benefits of Using Specific Materials in Burner Manufacturing

When it comes to manufacturing bio ethanol burners, the choice of materials plays a crucial role in determining the efficiency, durability, and overall performance of the burner. In this article, we will explore the benefits of using specific materials in burner manufacturing, focusing on bio ethanol burners.

One of the key materials used in the production of bio ethanol burners is stainless steel. Stainless steel is known for its excellent corrosion resistance, making it an ideal choice for burners that will be exposed to high temperatures and ethanol fuel. The high thermal conductivity of stainless steel also ensures that heat is distributed evenly throughout the burner, resulting in more efficient and consistent burning of bio ethanol.

Another important material used in bio ethanol burner manufacturing is tempered glass. Tempered glass is highly resistant to thermal shock and can withstand high temperatures without cracking or shattering. In bio ethanol burners, tempered glass is often used as a protective barrier around the flame, providing a safe and visually appealing way to enjoy the flickering flames of the burner.

Ceramic is another material commonly used in bio ethanol burner production. Ceramic is an excellent insulator, helping to retain heat and improve the overall efficiency of the burner. Additionally, ceramic is a durable material that can withstand high temperatures, making it ideal for use in bio ethanol burners where heat resistance is paramount.

In addition to these primary materials, bio ethanol burners may also incorporate other materials such as brass or aluminum for specific components like burner pans or fuel canisters. Brass is favored for its aesthetic appeal and corrosion resistance, while aluminum is known for its lightweight and heat conductivity properties.

Overall, the choice of materials in bio ethanol burner manufacturing can have a significant impact on the performance and longevity of the burner. By selecting high-quality materials such as stainless steel, tempered glass, and ceramic, manufacturers can ensure that their bio ethanol burners are not only functional and efficient but also safe and visually appealing.

In conclusion, the careful selection of materials is essential in the production of bio ethanol burners. By choosing materials such as stainless steel, tempered glass, and ceramic, manufacturers can create burners that are not only efficient and durable but also safe and aesthetically pleasing. The use of high-quality materials in burner manufacturing helps to ensure that bio ethanol burners continue to be a popular and reliable choice for environmentally-conscious consumers looking to enjoy the warmth and ambiance of a clean-burning flame.

Considerations for Choosing Materials for Bio Ethanol Burners

Bio ethanol burners have become increasingly popular in today's world as a sustainable and environmentally friendly alternative to traditional fuel sources. These burners are designed to burn bio ethanol, a renewable and clean-burning fuel made from plant materials. When considering what materials are used in the production of bio ethanol burners, there are several key factors to take into consideration.

One of the most important considerations for choosing materials for bio ethanol burners is their heat resistance. Since bio ethanol burners generate heat as they burn fuel, it is crucial that the materials used in their production can withstand high temperatures without warping or deteriorating. Stainless steel is a common choice for bio ethanol burners due to its excellent heat resistance and durability. This material is also resistant to corrosion, making it ideal for outdoor use where the burner may be exposed to the elements.

In addition to heat resistance, another important factor to consider when choosing materials for bio ethanol burners is their safety. Bio ethanol burners are designed to be used indoors, so it is essential that the materials used in their production are non-toxic and do not release harmful fumes when heated. Materials such as tempered glass and ceramic are often used in bio ethanol burners for their safety features. Tempered glass is heat resistant and shatterproof, providing a protective barrier between the flames and surrounding environment. Ceramic is also a popular choice for bio ethanol burners due to its ability to absorb and distribute heat evenly, reducing the risk of hot spots and potential accidents.

Furthermore, when choosing materials for bio ethanol burners, it is essential to consider their aesthetic appeal. Bio ethanol burners are often used as decorative pieces in homes and outdoor spaces, so the materials used in their production should be visually appealing and complement the overall design of the burner. Materials such as brushed stainless steel, black powder-coated steel, and matte-finished ceramic are commonly used in bio ethanol burners for their modern and sleek appearance. These materials are also easy to clean and maintain, ensuring that the burner remains looking its best for years to come.

Overall, choosing the right materials for bio ethanol burners is essential to ensuring their longevity, safety, and aesthetic appeal. By considering factors such as heat resistance, safety, and visual appeal, manufacturers can create high-quality burners that provide a clean and efficient source of heat. Whether used indoors or outdoors, bio ethanol burners offer a sustainable and stylish alternative to traditional fuel sources, making them a popular choice for environmentally conscious consumers.

Emerging Trends in Material Innovation for Bio Ethanol Burner Production

Bio ethanol burners have become increasingly popular in recent years as consumers seek sustainable and environmentally friendly alternatives to traditional fuel sources. These burners utilize ethanol, a renewable and clean-burning fuel that is produced from plant-based sources such as corn, sugarcane, and barley. However, the materials used in the production of bio ethanol burners play a crucial role in their efficiency, durability, and overall performance.

Traditionally, bio ethanol burners have been made from stainless steel, due to its resistance to corrosion and high temperatures. However, as the demand for these burners continues to grow, manufacturers are exploring new materials and technologies to improve their design and functionality. One of the emerging trends in material innovation for bio ethanol burner production is the use of ceramic materials.

Ceramic materials offer several advantages over traditional stainless steel burners. They have a higher heat retention capacity, which means they can distribute heat more evenly and efficiently. This results in a more consistent and longer-lasting burn, making ceramic bio ethanol burners a popular choice for consumers looking for high-performance heating solutions.

In addition to ceramic materials, manufacturers are also experimenting with new composite materials for bio ethanol burner production. These materials combine the strength and durability of traditional metals with the lightweight and versatility of polymers. This allows for more creative and innovative designs, as well as increased energy efficiency and cost-effectiveness.

Another emerging trend in material innovation for bio ethanol burner production is the use of recycled and sustainable materials. As consumers become more environmentally conscious, they are seeking products that are made from recycled or renewable sources. Manufacturers are responding to this demand by incorporating recycled steel, aluminum, and other materials into their burner designs. This not only reduces waste and conserves natural resources but also gives bio ethanol burners a unique and eco-friendly appeal.

Furthermore, advancements in 3D printing technology are also influencing the materials used in bio ethanol burner production. 3D printing allows for complex and intricate designs that were previously difficult or impossible to achieve with traditional manufacturing methods. This opens up new possibilities for customization and personalization, as well as greater efficiency and precision in burner production.

Overall, the materials used in bio ethanol burner production are constantly evolving to meet the demands of a growing market. From ceramic and composite materials to recycled and sustainable options, manufacturers are exploring a wide range of materials and technologies to create innovative and high-performance bio ethanol burners. As consumers continue to prioritize sustainability and efficiency in their heating solutions, these emerging trends in material innovation will play a key role in shaping the future of bio ethanol burner production.

Conclusion

In conclusion, understanding the materials used in bio ethanol burner production is essential for both manufacturers and consumers. By using sustainable materials such as stainless steel, ceramic, and tempered glass, these burners not only provide a stylish and efficient way to heat your space, but also contribute to a cleaner and greener environment. As the demand for eco-friendly heating solutions continues to grow, it is important for companies to prioritize the use of sustainable materials in their production processes. By making informed choices about the materials we use, we can all play a part in creating a more sustainable future. So, next time you are in the market for a bio ethanol burner, be sure to consider the materials used in its production and choose one that aligns with your values and commitment to environmental responsibility.